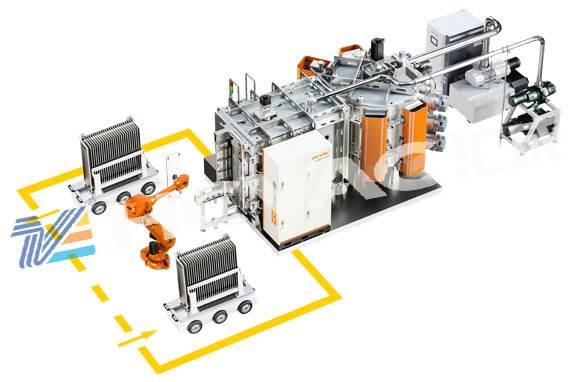

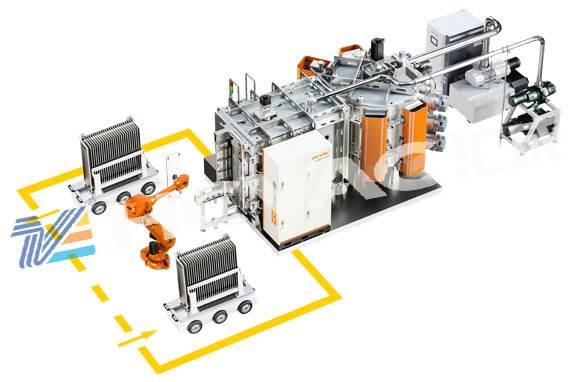

The thin film deposited by the optical pvd coating machine is a functional thin film that uses the effect of the thin film on light to work. Based on this optical functional film, manufacturers of coating equipment have manufactured various types of optical pvd coating machines according to market optical application needs. They are classified according to the process, including electron beam optical evaporation vacuum coating machines and magnetron sputtering optical pvd coating machines. There are two categories of coating machines. Because the application fields of optical pvd coating machines are relatively wide, the proportion of optical pvd coating machines in the market is also very high. Below, the editor of Huicheng Vacuum will introduce the application fields of optical films in detail:

The lenses of the optical instruments we see every day are coated with optical films. If the lens of a telescope is not coated with an optical film, when light shines on the lens, constructive interference will occur when light of certain wavelengths is reflected, which will increase the intensity of the reflected light and weaken the transmitted light, and other lights will produce complementary colors. , which will affect the imaging of the telescope.

Optical films can change the transmittance of light, enhance the transmission of excessively reflected light, and improve the transmittance. In this case, anti-reflection coating is used. The thickness of the film can be controlled to control which wavelengths of light are transmitted or reflected. Coating the lens can not only improve the imaging quality of the telescope, but also enhance the applicability of the telescope to various environments, such as snow. Too strong reflected light will make the telescope image dim and distorted, with serious chromatic aberration. Coating the telescope with a red film will These problems will be solved very well.

Optical films are widely used in lighting equipment, such as incandescent lamps, low-pressure sodium lamps, etc., which can make lighting equipment more energy-saving. Most of them are coated with a layer of anti-reflection coating that strongly reflects infrared light on the surface of the lamp. When light shines on it, constructive interference occurs, which enhances the reflected light and weakens the transmitted light, thereby enhancing the transmission of visible light. .

This can not only save energy but also change the energy distribution of the spectrum, so that the energy is mainly distributed in visible light and rarely in infrared light. It can even make the energy in infrared light zero, so the coated lamp is brighter than the uncoated one. . Among them, incandescent lamps mostly use tin dioxide film or silver film, and sodium lamps use silica film.

Optical films can not only be used in optical systems, but also have many applications in other fields, such as agriculture. We all know the important role of light in agricultural production. With the development of science and technology, many agricultural plantings are no longer as dependent on weather and seasons as in the past. Many fruits and vegetables are grown in greenhouses.

In order to make better use of light, a sunshade energy-saving curtain film was invented, which uses optical film technology. When the temperature in the greenhouse is too high for plant growth in summer, the sunshade film will reflect some infrared radiation and weaken the light intensity, thus causing the temperature inside the greenhouse to drop. When the temperature is too low in winter, the sunshade film will reflect the heat radiated from the ground back and prevent the heat from dissipating from the greenhouse, so as to increase the temperature inside the greenhouse. In this way, there is no need to manually heat the greenhouse so much, saving money. energy. Now a new type of sunshade energy-saving curtain film has been developed. The aluminum film plated on polymer materials has better energy-saving performance and temperature regulation effect, and has reached the international advanced level.

The thin films deposited by

optical pvd coating machines are not only the above categories, but also have many other applications, so I will not go into details here one by one.