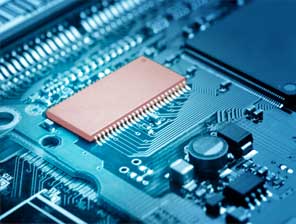

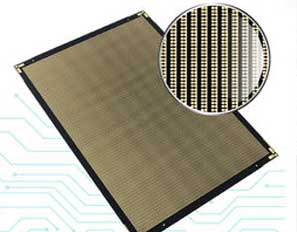

Load-lock type Sputtering System Compact multifunctional sputtering coating machine

Load-lock type Sputtering System Characteristic:

Redesign ease of use by leveraging traditional process data and proprietary technology

Increase productivity by installing a box mechanism (optional) in the load locking chamber

Support multi cathode stacking / simultaneous sputtering

The labor-saving operation is realized through the automatic processing of touch panel and formula input

Data recording is possible

Application:

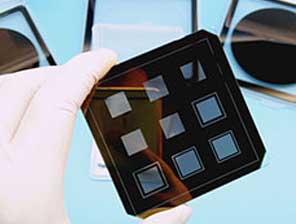

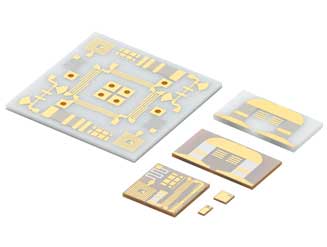

Electrode film forming / multilayer electrode and simultaneous film forming applications

Dielectric film forming, insulating film, passivation, protective film, etc.

Used for R & D and small-scale production of electronic components

| Main modules | |

| Arc | HiPIMS |

|

The innovative APA evaporator technology (Advanced Plasma Assisted) is based on cathodic vacuum arc and offers diverse development possibilities for new layer architectures. Benefits: ●High target utilisation result in low target costs ●High deposition rates ●Adjustable magnetic fields ●Short target changing times ●High plasma density ●Reduction of macro-particles ●Excellent coating adhesion |

HiPIMS stands for High-Power Impulse Magnetron Sputtering. Benefits: ●High ionisation rate (similar to arc) ●High power densities from 100 to 1000 W/cm2 ●Very high plasma density ●Layer structures adjustable by plasma parameter settings ●Very smooth coatings ●Excellent coating adhesion ●Deposition of dense coatings at low substrate temperatures |

| Additional modules | |

| Sputter | Nitriding |

|

In the sputtering process, atoms are extracted from a target by bombardment with high-energy ions (Ar) and transformed into the gas phase. By combining the sputtered material with additional gases, a coating is deposited on the substrate. Benefits: ● A wide range of materials can be sputtered ● Diverse process variants available ● Smooth coatings ● Good coating adhesion on combination with power etching prozess AEGD |

With the nitriding module, a plasma nitriding process can be performed before a PVD and/or PACVD coating process in one system and one batch. Thereby a hardened layer can be produced which offers excellent support for the subsequent PVD/PACVD coating. Benefits: ● Optimisation of tool and component properties ● Substitution of expensive base materials ● Significantly longer lifetimes ● All PVD coatings can be applied |

| DLC | ta-C |

|

DLC stands for Diamond-Like Carbon and refers to a group of extremely low friction amorphous carbon coatings. With the DLC module, different DLC coatings can be produced by using PVD and/or PACVD processes. Standard DLC coatings consist of metal free or metal containing carbon coatings. Benefits: ● Excellent coating adhesion ● High wear resistance ● Low coefficient of friction ● Smooth coatings |

ta-C stands for tetrahedral amorphous carbon without hydrogen and refers to a group of extremely hard and low friction amorphous carbon coatings. With the ta-C module different ta-C coatings can be produced. Benefits: ● For higher temperature environments than DLC ● Very high wear resistance ● Excellent coating adhesion ● Smooth coatings |