Customer base

Injection molding related parts and related supporting manufacturers, PVD coating processing enterprises

Solution

Injection molding related parts and related supporting manufacturers, PVD coating processing enterprises

Provide PVD coating equipment and technology for enterprises

According to the characteristics of injection molding related parts industry products and the growing customer demand, we have developed a variety of equipment technology and coating process

Injection molding is a kind of molding method for industrial products. Rubber injection molding and plastic injection molding are usually used for products. Injection molding can also be divided into injection molding, pressing and die casting. Injection molding machine (hereinafter referred to as injection molding machine or injection molding machine) is the main molding equipment to make thermoplastic or thermosetting materials into various shapes of plastic products by plastic molding mold. Injection molding is realized by injection molding machine and mold.

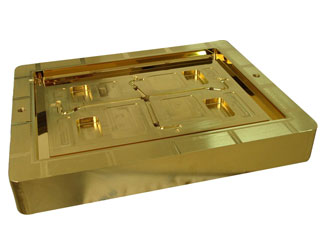

Huicheng vacuum coating machine is used in injection molding industry. Injection molding tools need durable, high quality, reliable and solid surface solutions to ensure high productivity of stamping machine. Syn vacuum is essential for die casting, blanking, trimming or stamping applications, and can be used for special tools, small batch or mass production. Moreover, the service life is prolonged by excellent wear protection of the functional surface, cutting edge and drawing radius. The production reliability is improved by reducing tool load and monitoring visual wear at any time. Surface quality can be improved by excellent wear protection and reduced cold welding.