News centres

In the context of China’s “Dual Carbon” strategy and a worldwide energy transformation, the new energy sector is moving beyond capacity expansion toward high performance, extended lifespan, and sustainable manufacturing. Lithium-ion batteries, hydrogen fuel cells, and photovoltaic cells make up the three core pillars of the new energy landscape, with their key materials and surface engineering technologies emerging as a key battleground for industrial leadership.

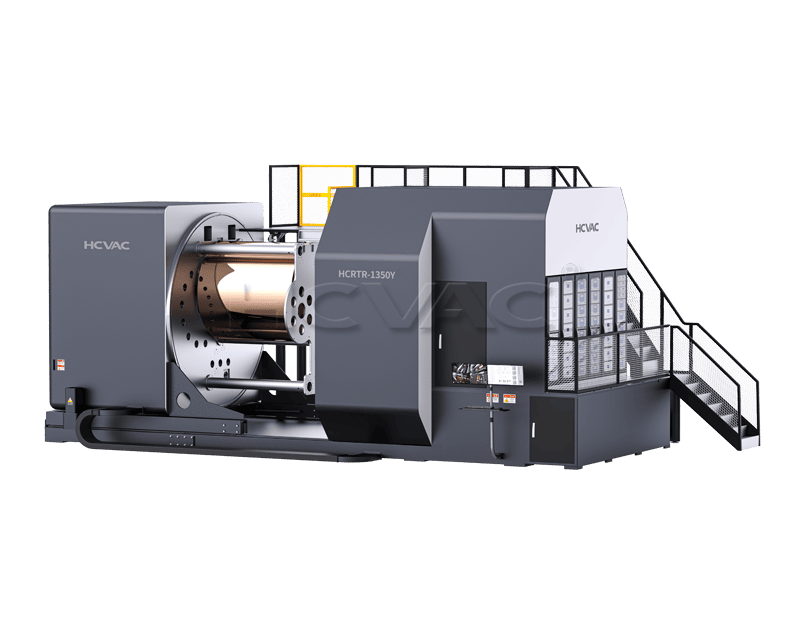

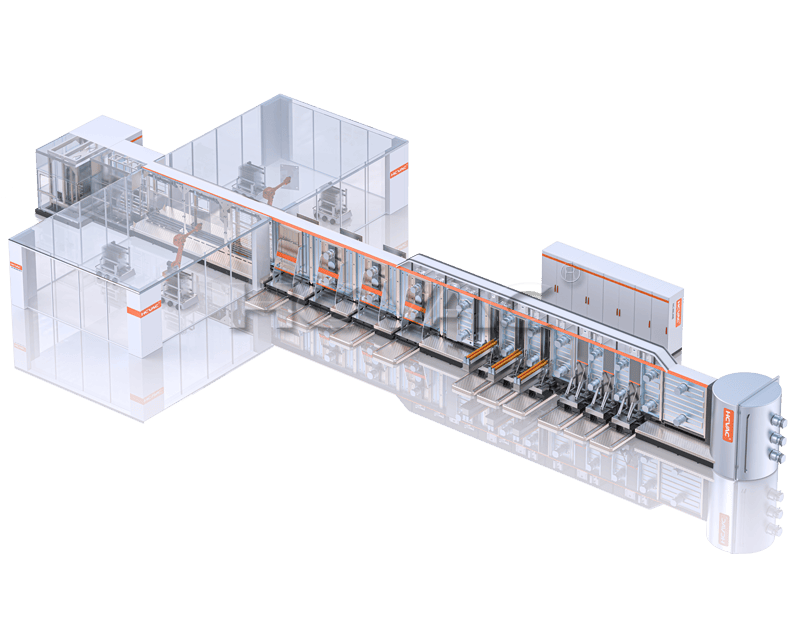

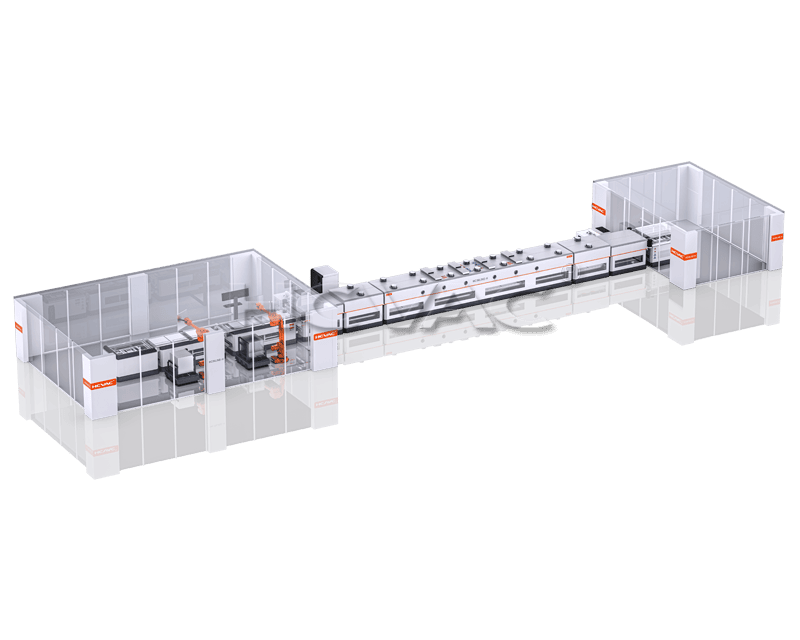

HCVAC, a leading Chinese manufacturer of vacuum coating equipment, leverages its proprietary PVD (Physical Vapor Deposition) technology platform to create a “Trio” process matrix addressing the core segments of the new energy sector

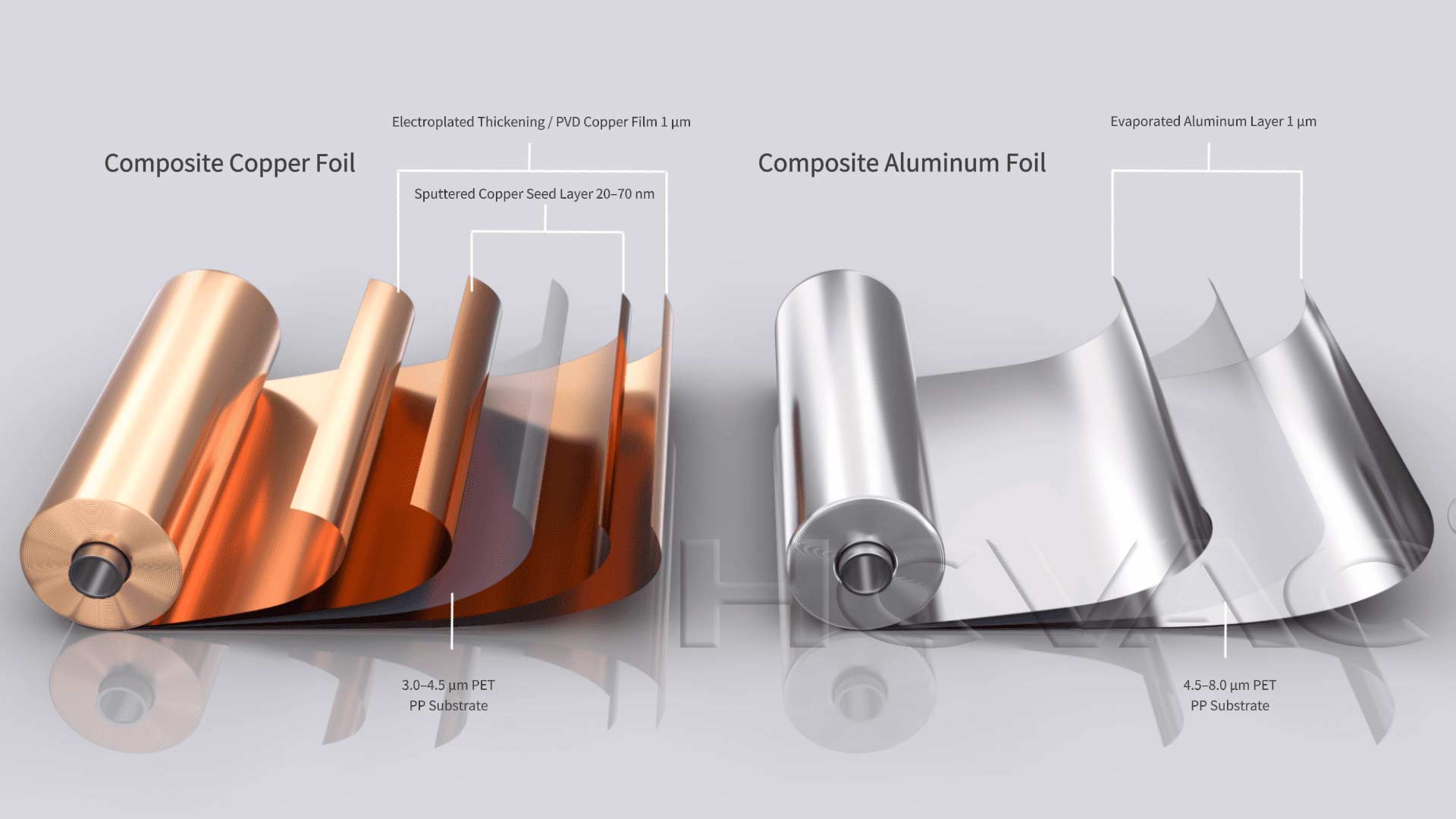

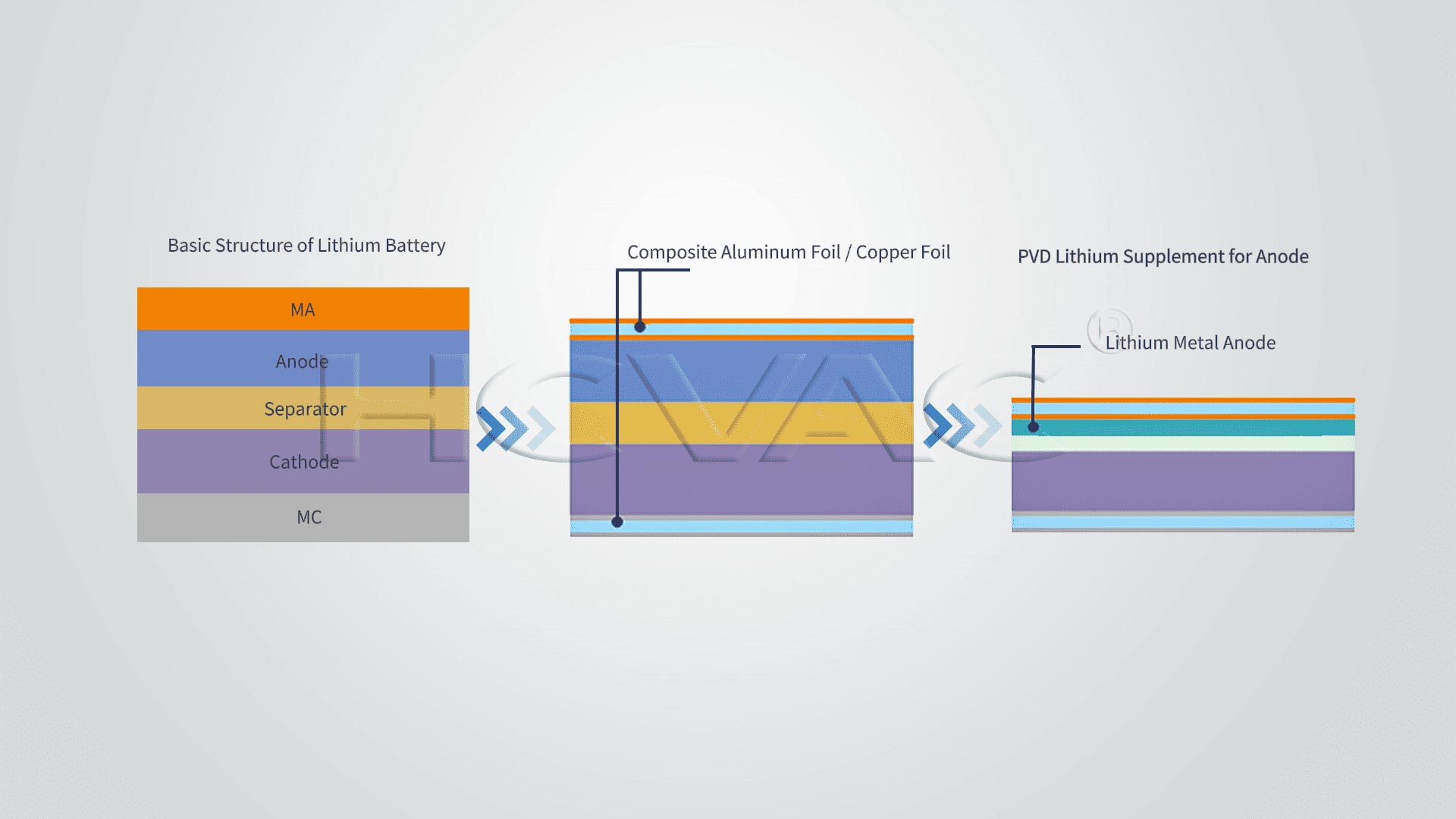

• PVD Composite Current Collectors — Enhancing energy density and battery cycle lifePVD Composite Current Collectors: The Conduction Pathway for High-Performance Lithium Batteries

In the fields of power batteries and energy storage batteries, traditional aluminum foil (cathode) and copper foil (anode) current collectors are increasingly showing their limitations under demands for higher energy density, faster charge/discharge rates, and improved safety.Composite current collectors — featuring a polymer + metal + functional coating structure — together with PVD lithium-compensation technology for anodes, are emerging as the next-generation solution.

Key Technology Highlights:

• Highly uniform metal deposition: Cu, Al, Ni and other metals are deposited on flexible substrates such as PET film, with thickness uniformity better than ±2%.Application Areas:

• Power batteries: High-nickel ternary, lithium iron phosphate (LFP), and silicon-carbon anode systems

Market Outlook:

According to BloombergNEF, by 2030 global lithium battery production capacity will reach 5,500 GWh, driving demand for composite current collectors to 77 billion m², with PVD equipment penetration expected to exceed 30%.

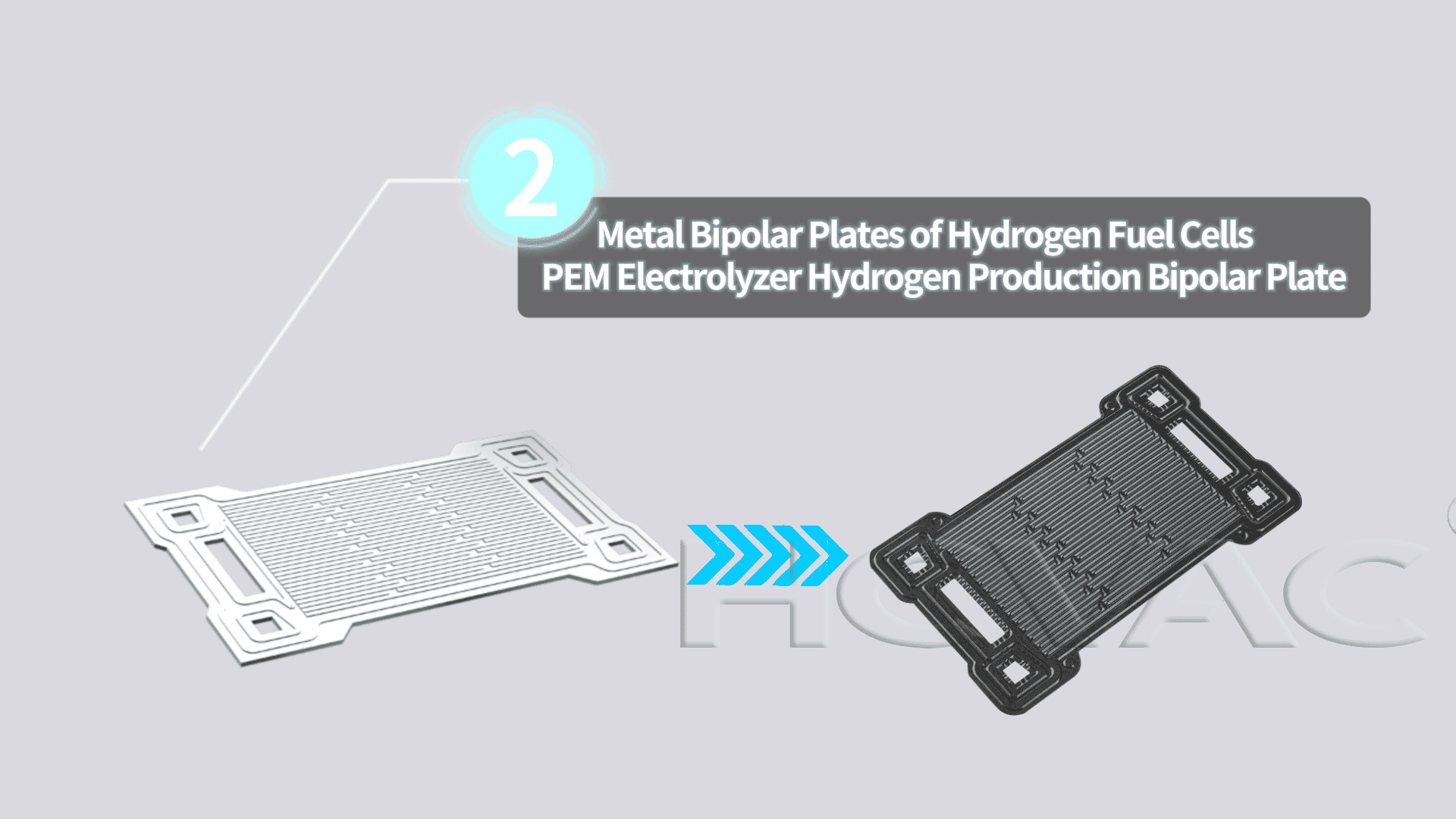

GLC Bipolar Plate Coatings: Durability and Efficiency for Hydrogen Energy Core Components

In both hydrogen fuel cells and PEM electrolyzers, metal bipolar plates perform multiple roles — conducting electricity, distributing gases, and providing sealing. However, their service life and efficiency have long been constrained by electrochemical corrosion and rising contact resistance.

Key Technical Highlights:

Applications:

The IEA projects that global green hydrogen production will exceed 15 million tons per year, and hydrogen fuel cell vehicle stock will surpass 5 million units by 2030. This growth will drive rapid expansion in the bipolar plate coating equipment market, creating substantial substitution opportunities for domestically manufactured equipment.

TCO Photovoltaic Coating: An “Anti-Reflection + Light-Enhancement” Solution for Cost-Performance Optimization

In photovoltaic manufacturing, surface coating processes directly determine module conversion efficiency and the levelized cost of electricity (LCOE). High-performance anti-reflective (AR) and TCO layers can significantly increase light absorption and reduce reflection losses.

Key Technical Highlights:

• Multi-Technology Coverage: Crystalline silicon (PERC, TOPCon, HJT), thin-film (CdTe, perovskite), flexible modules, and BIPV.

Conclusion: Green Process Matrix Driving Industrial Upgrade

The "Triple-Pillar Strategy" for new energy batteries represents not only HuiCheng Vacuum's technological roadmap but also a critical development vector for the entire industry:

• PVD composite current collectors — advancing lithium batteries toward higher energy density and longer cycle life• GLC-coated bipolar plates — enabling hydrogen energy to scale up and reduce costs

• TCO photovoltaic coatings — boosting PV module efficiency while lowering LCOE

Driven by the three strategic pillars of intelligent manufacturing, green processes, and localized substitution, HCVAC is accelerating the creation of a full-industry-chain vacuum coating solution, empowering China’s new energy sector to achieve high-quality breakthroughs in the global market.

About Us

HCVAC is committed to becoming a global leader in high-end vacuum application technologies. The company specializes in the R&D and intelligent manufacturing of PVD and ALD equipment, with product lines covering optical coatings, functional films, roll-to-roll coating, atomic layer deposition (ALD), and continuous sputtering production lines. These solutions are widely applied in advanced industries such as consumer electronics, automotive, architecture, energy, and semiconductors.

With outstanding technological innovation capabilities, HCVAC has been recognized as a National High-Tech Enterprise and a Guangdong Provincial Engineering Technology Center. In June 2024, the company was successfully listed on the ChiNext board of the Shenzhen Stock Exchange.

Driven by a global vision, a professional team, and a high-standard service system, HCVAC continues to push the boundaries of industry innovation and works hand in hand with customers to create greater value for the future.

Email: info@hcvacuum.com | WhatsApp: +86 133 1668 9188