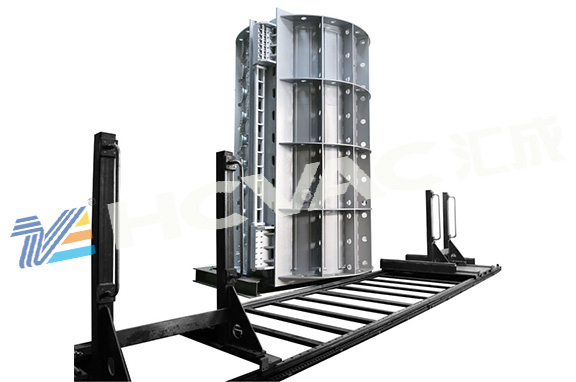

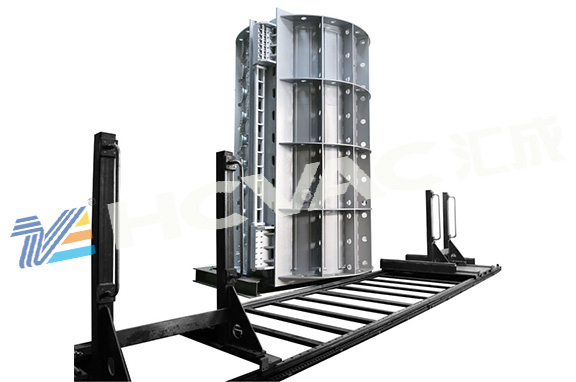

The magnetron sputtering pvd coating machine for solar glass heat collector tube includes vacuum container, turret system, magnetron sputtering target, vacuum acquisition system and power supply, electric control and vacuum measurement, etc. The vacuum container is a work room that realizes the coating of glass tubes. The magnetron sputtering target, turntable system, vacuum measurement and gas distribution system of the vacuum coating machine are closely connected with the vacuum container. The magnetron sputtering target of the pvd coating machine is placed in the center of the bottom plate of the vacuum container. The target is surrounded by a turret system for fixing glass tubes. It can place 30 glass tubes with a diameter of 58mm at a time. The surrounding of the turret system is the inner wall of the container. There is an inflatable pipe with a gas distribution system, which is carefully designed and configured to ensure the uniform distribution of the atmosphere in the entire container; the rear side of the vacuum chamber container is an air extraction port connected to the vacuum air extraction system.

The inner cavity size of the vacuum container of the pvd coating machine is φ900mm X 2500(h)mm, which can coat solar heat-absorbing films for various glass tubes with a length of 1500-2000mm. It is a vertical front door. Watch the whole process of coating.

The pumping system of the pvd coating machine adopts a vacuum unit with KT-600 oil diffusion pump as the main pump, including K-600 oil diffusion pump, Roots pump with pumping speed of 300L/s, 2x70 rough pump and 2x 30 to maintain the pump and related valves and pipes, its ultimate vacuum can reach 5 X 10-4Pa. The container can be pumped from the atmosphere to a background vacuum of 6.67 X10-3Pa within 25min.

The structure of the magnetron sputtering target of the pvd coating machine adopts the cathode structure of the permanent magnet coaxial cylindrical target. The length of the target is 2000mm, the inner diameter is 60mm, the outer diameter is 70mm, and the target material is aluminum. The electromagnetic steel adopts strip-shaped NdFeB, and the target core can be rotated 360o in all directions to ensure uniform etching of the target surface, and the target utilization rate can reach more than 80%. Threads are used for connecting the target tube and the target body, which is convenient for installation and disassembly.

The turret is fixed to the motor and reducer on the back side of the coating chamber bracket. Through the belt drive, the rotational torque is transmitted to a rotating shaft directly leading to the interior of the vacuum container, and the revolution of the turret is realized by the rotation of the main turntable.