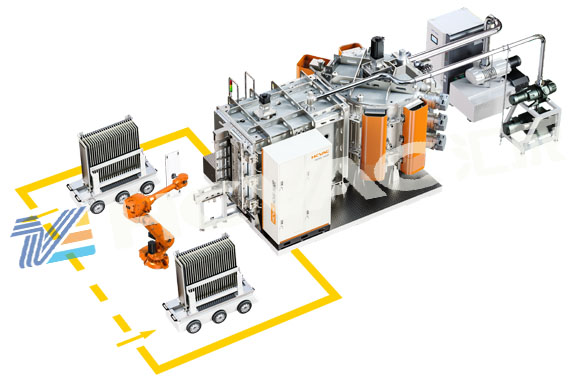

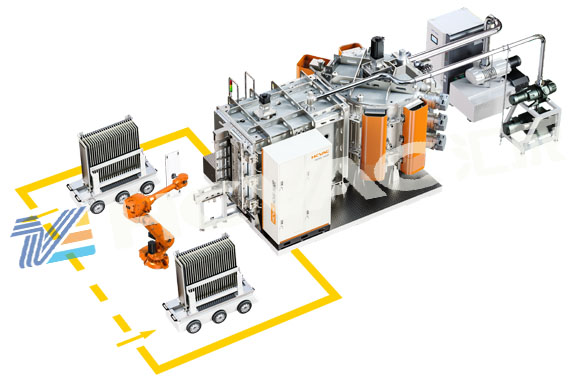

Magnetron sputtering web pvd coating machines are widely used in metal strips, packaging, flexible electronics, holographic anti-counterfeiting, capacitive films and other fields. Therefore, we often refer to web coating machines applied to metal strips as metal strip web pvd coating Machine, the web coating machine applied to the packaging field is called packaging web vacuum coating machine, the winding coating machine applied to the flexible electronics field is called the flexible electronics web coating machine, etc. The application fields are different and the names are different. However, the coating technologies are similar. Below, the editor of Huicheng Vacuum will introduce the characteristics of the magnetron sputtering web vacuum coating machine in detail:

Magnetron sputtering coil coating uses magnetron sputtering (DC, intermediate frequency, radio frequency) method to deposit various metals, alloys, compounds, ceramics and other materials onto flexible substrates for single or multi-layer coating. Compared with evaporation web coating equipment, magnetron sputtering web pvd coating machine has lower production efficiency and higher equipment cost. This is determined by the coating principle. However, magnetron sputtering has the advantages of low coating temperature, the ability to place multiple targets at any position to continuously coat multi-layer films, a wide adaptability range of coating materials, controllable film thickness, fineness, uniformity, and firm adhesion.

The

magnetron sputtering web pvd coating machine can use the magnetron sputtering method to plate various dielectric films on flexible substrates, such as SiO2, Si3N4, Al2O3, SnO2, ZnO, Ta2O5, etc.; metal and alloy films such as Al, Cr, Cu, Fe, Ni, SUS, TiAl, etc.; use ITO, AZO and other ceramic targets to coat transparent conductive films; use multi-layer optical film structures to coat AR anti-reflective films, HR high-reflective films, AR+ITO high-transparent conductive films, low Radiant Low-E and solar control films, etc. Mainly used for film on front guards and glass doors and windows of cars, trains, ships, etc., film on building doors, windows and curtain walls, anti-static and electromagnetic films, decorative films and packaging films, solar greenhouse films, electric heater films, anti-frost and fog transparent films, Transparent electrode films are used for FPD flat panel displays, and optical multilayer films are coated on metal strips to make thin-film solar cells, etc. For example, ITO transparent conductive film can be used as a luminescent material. Coating SiO2 on the surface of cotton cloth can be made into protective clothing against electromagnetic radiation. Ni-plated sponge can be made into nickel-metal hydride batteries after being wound. Base materials plated with various materials can be made into e-books, flexible display devices, etc.