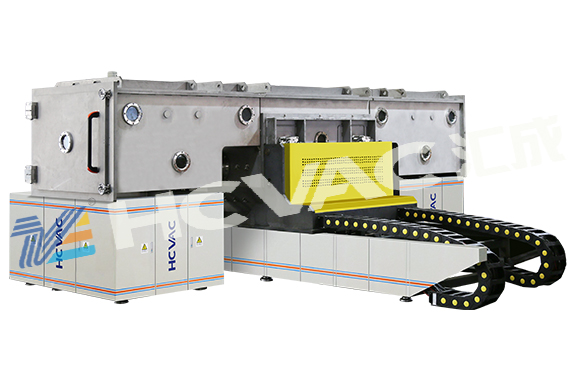

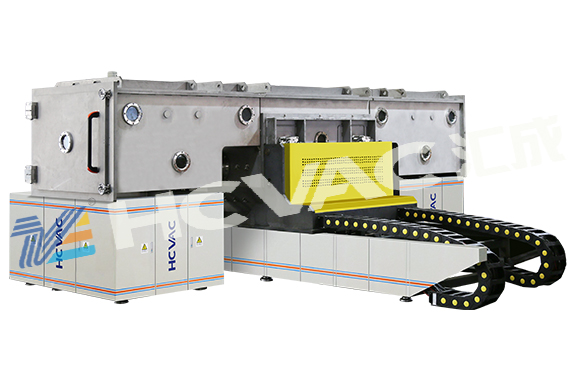

wed coating machine are widely used in various industries, such as: metal belts, packaging materials, surface decoration materials, hot stamping materials, textiles, capacitors, etc. The base materials for plating are different, and different types of winding vacuum coating machines are used , then the configuration is naturally different. What accessories are included in the general standard winding vacuum coating machine? Below, the editor of Huicheng Vacuum will give you a detailed introduction:

1. Winding system

The winding system is mainly composed of unwinding rollers, rewinding rollers, coating drums, guide rollers, tension measurement (control) rollers, flattening rollers and resistance test rollers driven by DC motors. Its function is to follow a certain speed and After the base film is transported to the coating area by tension for plating, the coated base film is then rolled up into a cylindrical roll film. By controlling process parameters such as film winding speed, tension, and the angle of the flattening roller, wrinkles can be avoided and a neatly rolled film roll can be obtained.

2. Speed control and tension control

Speed control: The constant linear speed of the strip substrate is the primary condition to ensure uniform film thickness. The speed control of strips in the winding system mostly adopts constant speed control based on current control. The speed can be set in advance and automatically adjusted according to the requirements of the product.

Tension control: Film tension control is a key issue in roll coating equipment. Tension control is related to the film's deviation, ribbing, wrinkles and other phenomena.

3. The evaporation system consists of the evaporation source holder (electrode), evaporation source, wire feeding mechanism, etc.

4. Vacuum chamber opening mechanism of PVD coating equipment: The opening mechanism of a large double-chamber semi-continuous evaporation coating machine generally consists of a vacuum chamber body, a winding mechanism, a large sealing plate, a power cabinet, a travel switch and a trolley. According to the width of the basic coating material, it is determined whether a single door or a double door can be opened. Most common vacuum chambers of winding coating machines have a single door open, and the evaporator is still in the coating chamber.

5. Shielding component: It is necessary to shield uncoated stripes or meshes on the film. This is a special requirement for capacitor films. The shielding stripes of ordinary capacitors extend along the longitudinal direction of the base film. The shielding stripes of safety capacitor films It's a reticulated pattern.

6. pvd coating machine system: Generally, the winding chamber and coating chamber of the

wed coating machine each have an independent vacuum pump set. Usually, the main pump of the evaporation chamber of the vacuum pumping system used in domestic and foreign roll-up coating machines is a measurement diffusion pump, and the main pump of the roll-up chamber is an oil diffusion jet pump with a high pumping speed.