Optical pvd coating machine magnetron sputtering technology and equipment occupy an increasing share in the field of precision optics and consumer optoelectronic thin films. Magnetron sputtering technology is divided into DC, medium frequency and radio frequency coating technologies. DC magnetron sputtering technology is mainly aimed at pure metal film layers, such as copper, nickel, chromium, etc. Medium-frequency magnetron sputtering technology mainly coats compounds and alloy films, while radio frequency coating technology mainly coats insulating material films. The target materials are different, and the coating technologies used are different, so that you can produce the products you want. Effect.

The magnetron sputtering film deposition process is simple to control, has high particle energy, and the obtained film structure is dense and stable, and can be deposited at low temperature. Because of the advantages of low film temperature and dense film structure, this technology is widely used in the market, especially in the field of optical precision.

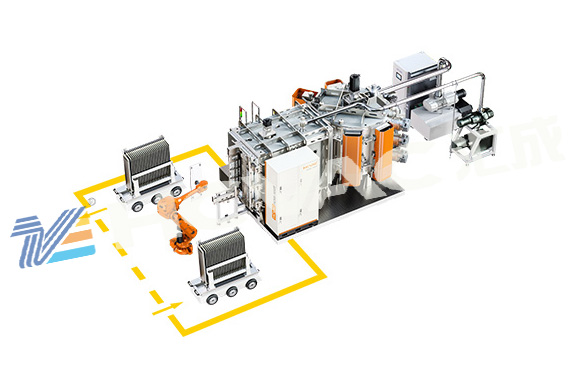

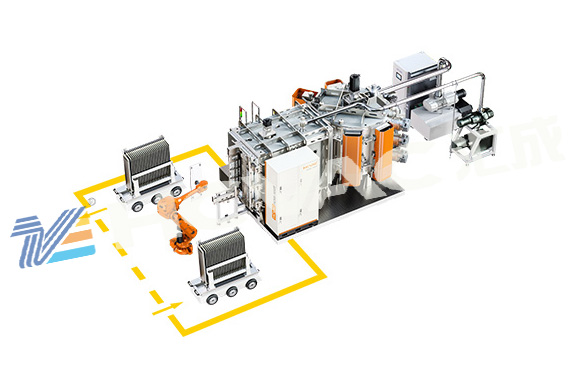

Compared with ordinary flat target devices in the industry, the rotating cathode device has significantly improved the target service life and utilization efficiency; the customizable substrate workpiece rack structure can be customized to maximize the space for customer products to be placed; fully automatic and integrated lifting The lifting turret device greatly reduces the time of opening and closing the machine door, greatly improving production efficiency and process stability; Huicheng's patented ion source has a wide working range, energy balance, high ionization rate, ultra-stable working efficiency, low energy consumption, etc. Features.

The HCAR-1800 magnetron sputtering

optical pvd coating machine can accurately control the film thickness using time to meet the design process requirements, save crystal control and light control links, and save customers a large amount of film thickness meter consumables; it can produce high refractive index High-rate nitriding film to improve film hardness performance; low-temperature film formation, suitable for various purposes; patented device for automatically adjusting gas flow to maintain stable target voltage and ensure film formation quality; optional "external adjustment mechanism for correction plate".

Sputter deposition systems are equipped with multiple cylindrical targets on the side walls to increase deposition rates and multi-layer coatings. The system is equipped with DC pulse or RF power circular cathodes, vertically mounted substrates and cylindrical cathodes to maximize Minimize particle contamination during the coating process.

AR film (substrate glass transmittance >91.5%), 420-680nm band, single-sided average transmittance >95%, reflectivity less than 0.5 (average)%; double-sided average transmittance >98%, reflection The rate is less than 0.5 (average)%; Color film or gradient color film, subject to customer sample, five consecutive furnaces with random positions or full furnace, color difference ΔE<1.2; boiling test: boiling at 80℃ for 30min, 3M hundred grid test (1*1mm) Greater than 4B.