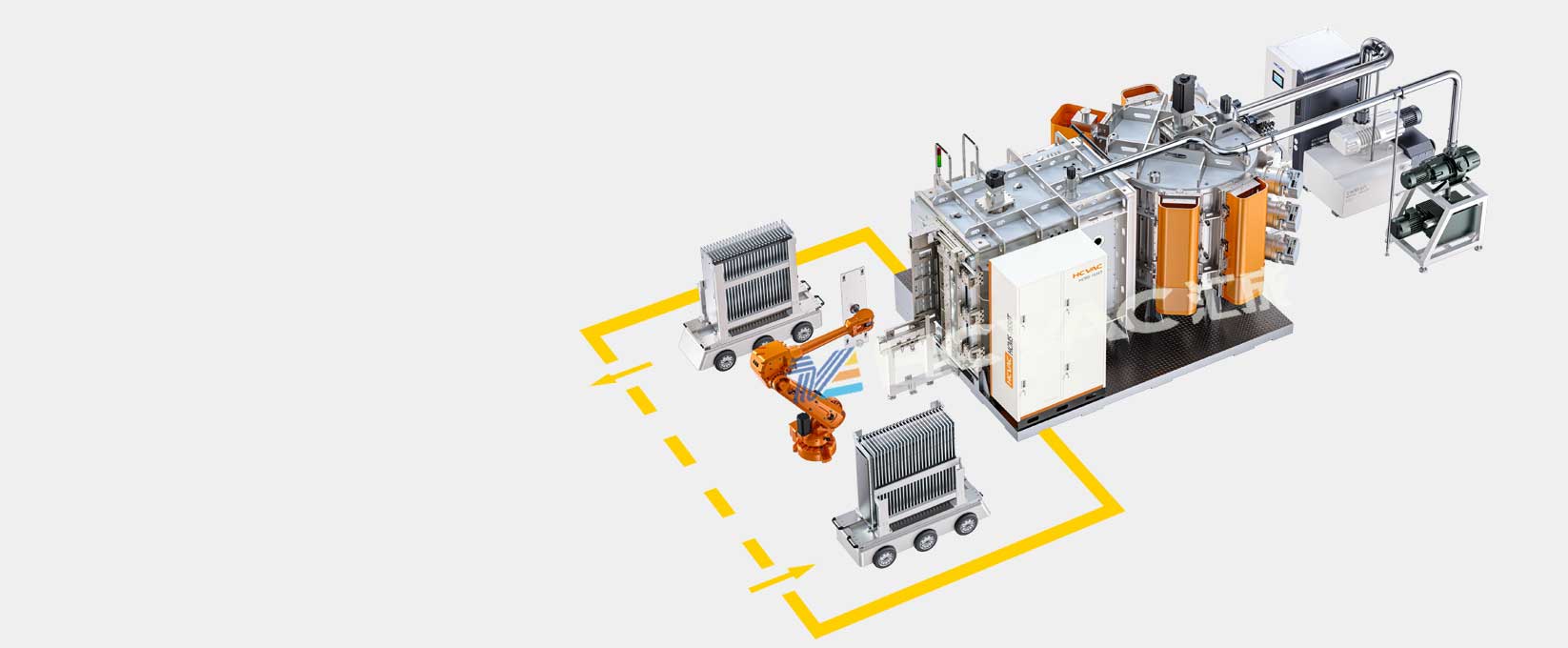

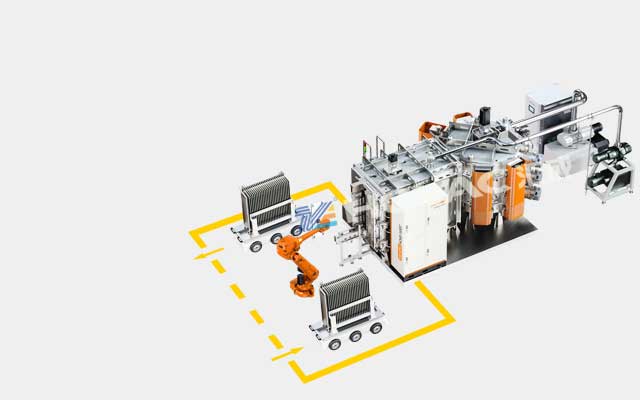

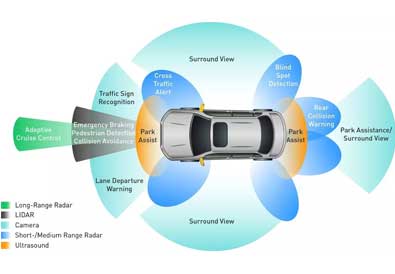

Intelligent automobile component coating machine

It has the oxidation mode after RF-ICP Assisted Magnetron sputtering, high deposition rate and matching optical properties. It is suitable for car cover glass and 3C front cover glass to deposit ar film. Ar film can be either ordinary SiO2 + Nb2O5 film or hard SiO2 + Si3N4 film. At the same time, it is also suitable for the processing of 3C product back cover color film (including gradient film) and NCVM film.

Compared with the ordinary plane target device in the industry, the service cycle and utilization efficiency of the target material of the rotary cathode device are significantly improved; the customized structure of the base plate work-piece rack can provide customers with the maximum utilization space for their products; the fully automatic lifting and lifting rotary rack device can greatly reduce the opening and closing time of the machine and greatly improve the production efficiency and process stability; Huicheng patent is issued The sub source has the characteristics of wide working range, energy balance, high ionization rate, super stable working efficiency and low energy consumption.

It can precisely control the film thickness by time to meet the design process requirements, save crystal control and optical control links, and save a lot of consumables for film thickness meter; it can produce high refractive index nitrided film to improve the hardness performance of film; it can form film at low temperature to cope with various uses; it can automatically adjust the gas flow patent device to maintain stable target voltage to ensure the film quality; it can also select "correction plate" External adjustment mechanism ".