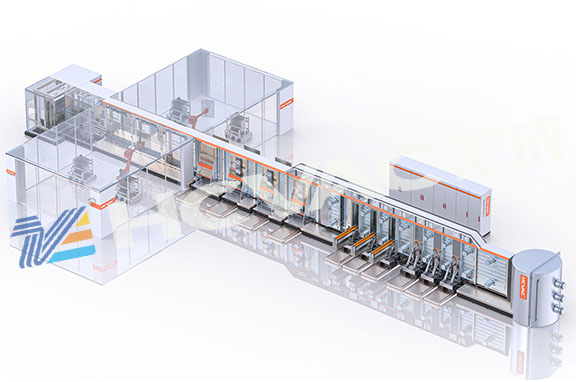

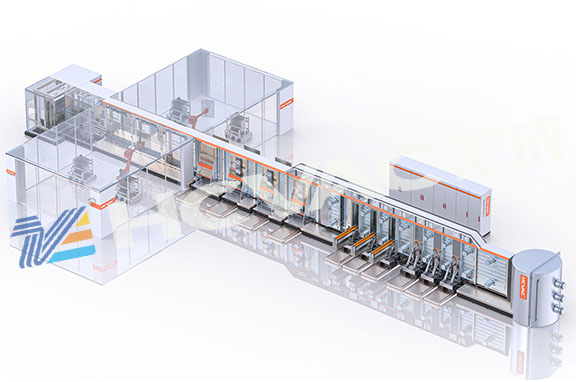

What we want to talk about today is what advantages the continuous coating machine has in the selective plating process. The continuous vacuum coater model is relatively large, and the issues to be considered when purchasing this equipment may need to be more comprehensive. Because the model is large, the cost of natural investment is also quite large, so the customer is very rational when it comes to continuous coating machine.

The continuous coating machine is a kind of equipment specially used for precision electroplating after various strips (copper strip/stainless steel strip) are coated and processed. Its principle is to stick the PVC film to the section of strips that do not need electroplating after cutting and forming with a cutter to play a shielding role.

This equipment makes the precision of the electroplating area up to 0.1mm, which is very effective in reducing the cost of precious metals and the cost of material electroplating failure. The plating area is not limited by the equipment of the line body, the film thickness and uniformity can be effectively controlled, the plating seeds can be selected at will, the plating seeds that can be dipped in the plating line can be coated and selected, and tin or nickel/gold/silver/palladium nickel can be selected after copper and nickel plating, At the same time, the products processed by this process have very clear interfaces, which can effectively solve the problems of ripple/inaccurate selection/missing plating/electroplating peeling/film thickness not meeting the requirements and unclear interfaces caused by liquid level selective plating. It is applicable to various strip electroplating processing.

What are the advantages of continuous coating machine?

(1) The thickness of the electroplated film is not limited. It can have the advantages of wheel type spot plating and solve the problem that the film thickness of wheel type selective plating cannot be achieved. It can be electroplated by adding ultrasonic wave in the way of immersion plating, and the film thickness is well controlled.

(2) The method of immersion plating is reliable, the conductivity of immersion plating is good, uniform, stable and reliable, and the cost of electroplating failure and returns are greatly reduced;

(3) The plating area can be adjusted at will. The plating area of the plating product can be accurately changed at any time without repeated opening of the plating die, or modification of the equipment, or repeated adjustment of the brushing equipment due to inaccurate brushing.

(4) The configuration of the line body is not limited, and one film applicator can work with multiple machines. It is not restricted by the line body process flow, and it does not need to add additional wheel type plating equipment and open a separate plating mold;

(5) Electroplating varieties can be matched at will, and nickel, tin, gold, palladium and nickel can be selected at the same time. One process can meet the requirements for selecting electroplating in multiple areas, avoiding product scrap and rising cost of defective products caused by multiple processes.

(6) The plate with thickness of 0.05~3mm can be electroplated, which can solve the defect that the thick plate can not be bent by wheel type selective plating.

(7) Precise plating area, accurate and even plating area, no leakage electroplating, no need to strip gold, and the use of gold, silver and other metals is greatly reduced.

(8) The interface of selective plating is clear, and the product interface completed by film selective plating is clear, which can meet the precision requirements of high-end products.

(9) The cost of precious metals will be greatly reduced, the uniformity of film thickness will be well controlled, there is no need to strip gold after missing plating, the electroplating area is accurate, and the thickness of the electroplated film is easy to control. Many favorable factors will make the cost of precious metals greatly reduced, and the cost of precious metals will far exceed the price of the film.

(10) The selective plating of multiple areas can solve the electroplating requirements of wheel electroplating or other selective plating methods that cannot simultaneously select 4 to 8 areas. The selective plating of nickel, tin, gold, silver, or semi gold tin, selective nickel plating, selective tin plating and other electroplating processes can be completed at the same time.

(11) Nickel plating, tin plating, palladium nickel plating and other varieties are selected. Electroplating requires that the film thickness of more than 30u "be plated, which is a function that other wheel electroplating does not have. Using ultrasonic plus immersion plating, the film thickness of more than 120u" can be effectively selected.

(12) It attracts high-end products. At present, low-end products are highly competitive. Most electroplating plants cannot meet the requirements for electroplating accuracy of high-end products. It can reduce costs while meeting the requirements for electroplating accuracy of customers.