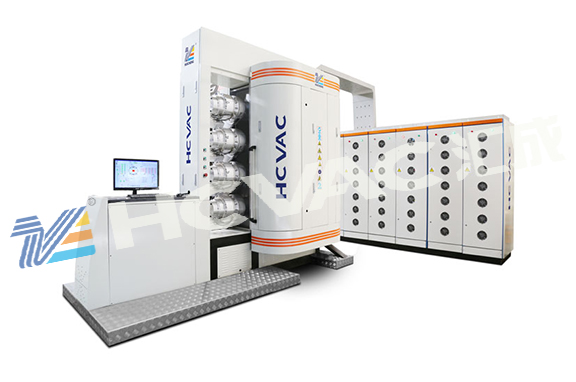

pvd coating machines have become an indispensable part of people's daily life. It can be said that without vacuum coating machines and coating technology, daily life may be very dull and the quality of people's life will also be greatly reduced. There are many types of coating machine applications in our daily life, such as decorative pvd coating machines, hard coating coating equipment, optical coating equipment, automotive pvd coating machine, continuous line coating equipment, semiconductor coating equipment, etc. The application industries and coating techniques are different, and the colors and functions of the coatings also vary greatly. Vacuum coating machines are ubiquitous in various industries, so what are the maintenance and precautions for using pvd coating machines?

pvd vacuum mainly includes several types: vacuum evaporation plating, sputtering plating, and ion plating. They all deposit various metal and non-metallic thin films on the surface of plastic parts under vacuum conditions, such as distillation or sputtering. Through this method, very thin surface coatings can be obtained, which has the outstanding advantages of fast speed and good adhesion. However, the price is also high, and there are fewer types of metals that can be operated. They are generally used as functional coatings for high-end products, such as as as as internal shielding layers. There are two common electroplating processes for plastic products: water electroplating and vacuum ion plating

Vacuum ion plating, also known as vacuum coating. Vacuum electroplating is now a popular practice, producing products with strong metal sensitivity and high brightness. Compared to other coating methods, it has lower costs and less environmental pollution, and is widely used in various industries

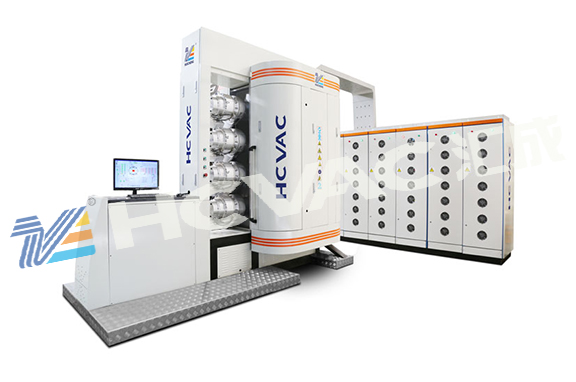

When repairing the pvd coating machine, we should pay attention to the following issues:

1. To install vacuum electroplating equipment correctly, the vacuum chamber, electrical control cabinet, etc. must be securely grounded.

2. To ensure the quality of the coating, vacuum electroplating should first pay attention to the hygiene of the vacuum chamber, and must strictly follow the technical requirements. The components inside the room should be cleaned with gasoline or alcohol, and vacuum plated and wiped dry before being loaded.

3. Before starting the pvd coating machine, check whether the mechanical rotating parts of each vacuum pump are normal, such as the seals in the transition drive of rotary vane pump and Roots pump. The vacuum coating must always check the oil quantity and grease to ensure normal operation.

4. Start the compressor with vacuum coating, and ensure that the air pressure for vacuum plating is above 0.4Mpa. Regularly discharge the accumulated water in the compressor's air storage tank.

5. After the vacuum coating work is completed, the vacuum electroplating room should be wiped clean, free of dirt, and maintain a low vacuum to avoid polluting the vacuum system and affecting vacuum performance.

6. The

pvd coating machine often checks the high-voltage microswitch for coating, which should be safe and reliable. If there is poor conductivity or damage, it must be replaced immediately.