News centres

With consumers trading up in home goods and premium décor demand growing, surface engineering is now the key driver of differentiation for décor brands.

According to research firms such as MarketsandMarkets, the global premium home and decorative hardware market is projected to exceed USD 250 billion by 2030, growing at a CAGR of about 5%.

Investment in surface treatments and new materials is growing faster than the overall market. They are now a key source of added value for premium décor.

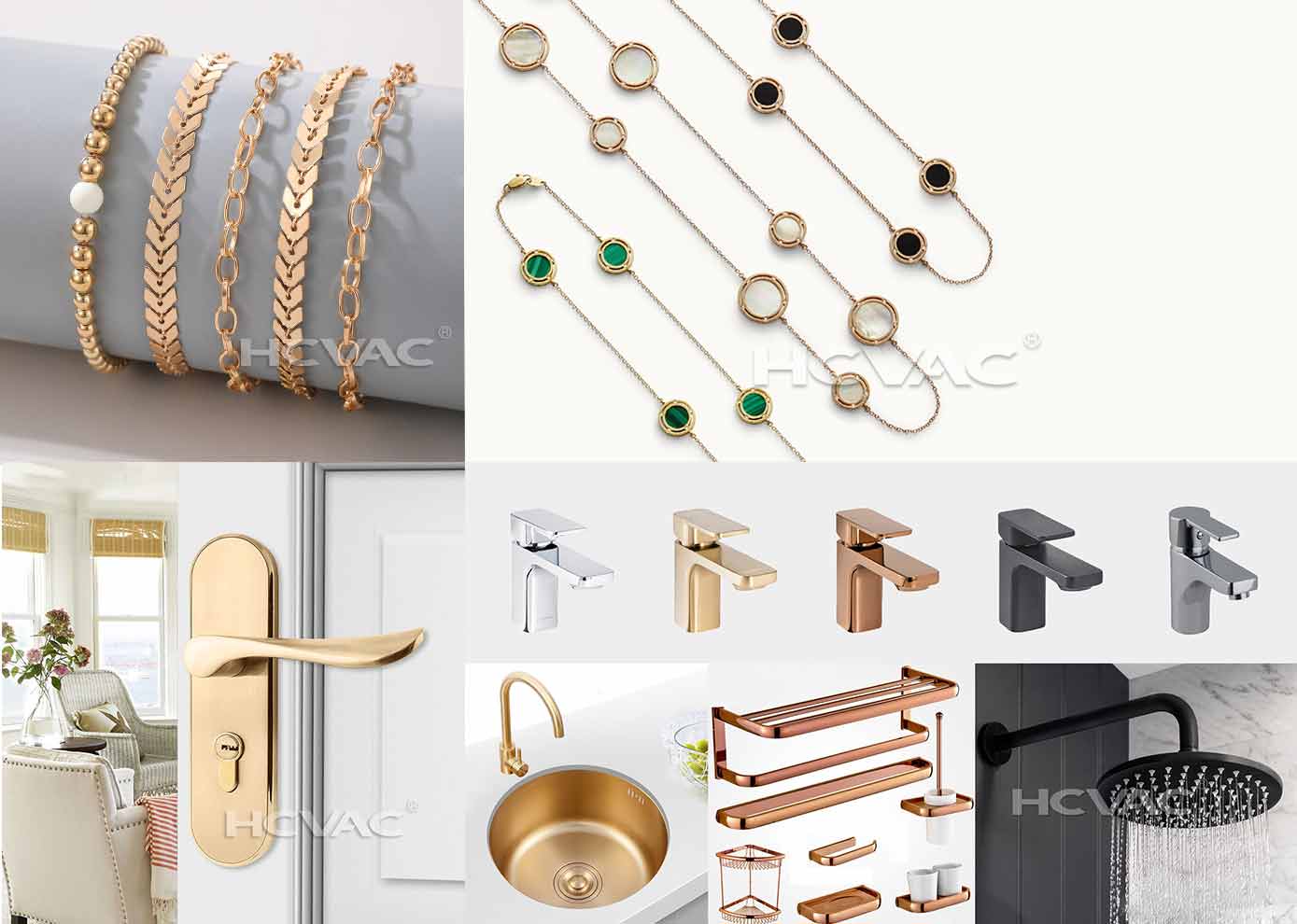

In categories such as bathware, door locks, furniture, lighting, and fine jewelry, consumers increasingly look for long-lasting shine, resistance to wear and corrosion, anti-fingerprint performance, and elegant color finishes. This trend is reshaping the entire value chain.

At the same time, traditional electroplating is struggling with environmental pressure and performance limits, while PVD (Physical Vapor Deposition) coatings are quickly becoming the mainstream choice.

PVD is setting a new benchmark in decorative and functional finishes. Compared with traditional electroplating, it delivers:

Environmentally compliant: Free from heavy-polluting processes such as hexavalent chromium, fully aligned with EU and US green standards.

Outstanding performance: Dense, well-bonded coatings that resist wear and corrosion under daily use.

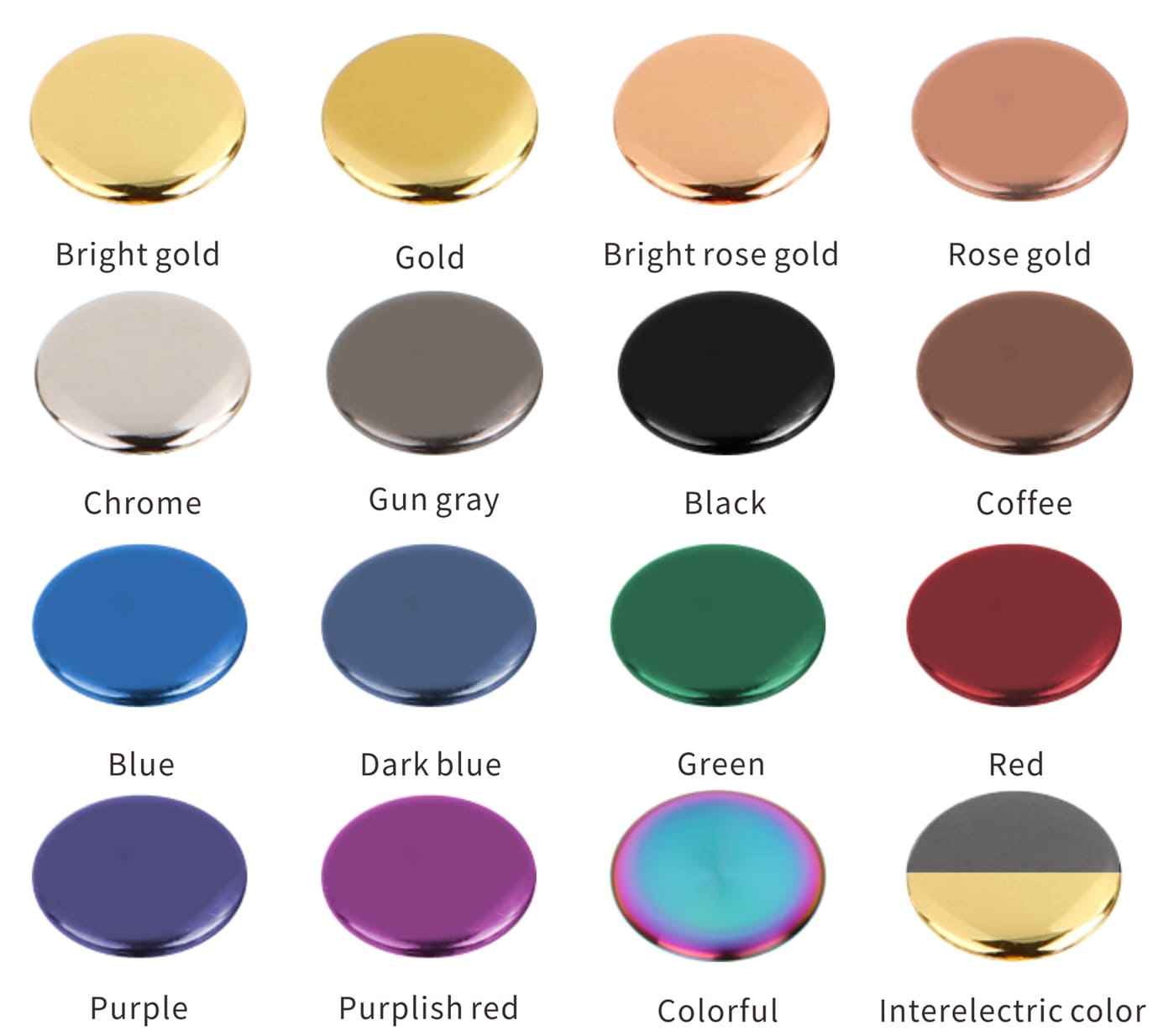

Rich aesthetics: A palette of premium finishes — gold, rose gold, gunmetal, champagne, even gradient effects.

Extended functionality: Anti-fingerprint coatings for better stain resistance and easy-to-clean surfaces.

Longer lifespan and durability: PVD coatings last 2–3 times longer than traditional electroplating.

This is why PVD is rapidly being adopted in jewelry, bathware, door locks, furniture fittings, lighting, and architectural décor.

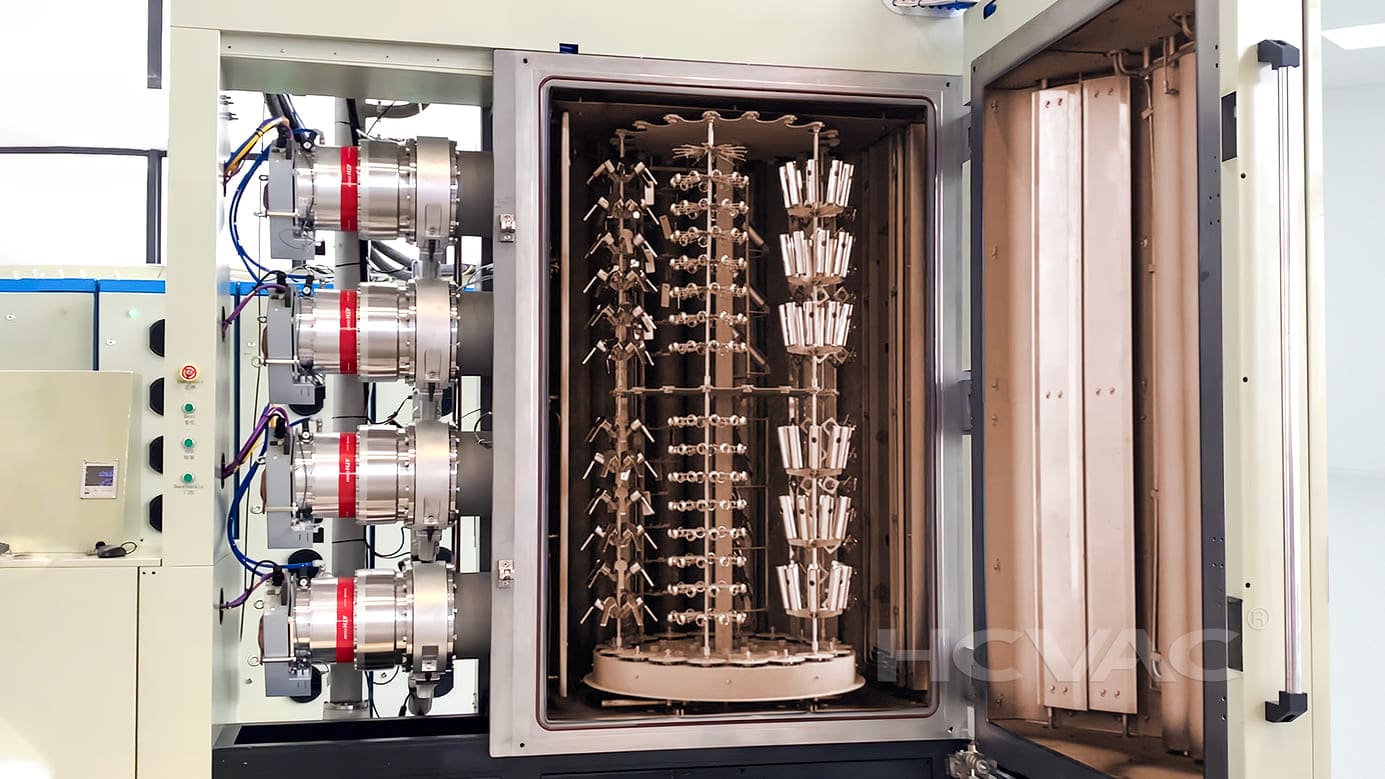

PVD technology is undergoing a transition from conventional processes to advanced high-energy techniques:

Vacuum Evaporation: Includes resistance heating evaporation and electron-beam evaporation. In a vacuum environment, materials are heated until vaporized and then deposited as thin films. Resistance evaporation is widely used for decorative metallic coatings, while electron-beam evaporation is better suited for high-melting-point materials and optical films. Typical applications include coatings for plastics, glass, ceramics, optical decoration, automotive interior and exterior components, and luggage accessories.

Cathodic Arc Ion Plating: Suitable for large-area, high-volume production. Commonly applied to enhance scratch resistance of frequently touched components such as door locks and handles.

Magnetron Sputtering: Provides excellent thickness uniformity, with deviations controlled within ±5%. It is widely applied in high-end jewelry, sanitary ware, hardware, and furniture handles.

HiPIMS (High-Power Impulse Magnetron Sputtering): Represents the future direction of PVD. It delivers ultra-dense coatings, superior adhesion, and an extended color range, making it the preferred process for premium decorative brands.

Looking ahead, the combination of HiPIMS and multi-arc ion plating is expected to become a core pathway for achieving differentiation and premiumization in the decorative industry.

HCVAC., as a leading domestic manufacturer of vacuum coating equipment, has established a comprehensive solution portfolio for the decorative industry:

Multi-process platform integration: Full coverage of vacuum evaporation, HiPIMS, magnetron sputtering, and ion plating, meeting diverse application requirements for high-end decorative coatings.

Breakthrough in anti-fingerprint coatings: Effectively reduces water and oil adhesion, enhancing the user experience of sanitary ware and door lock products.

Diverse alloy coating systems:

TiN (Golden Yellow): Luxurious and elegant, widely used in sanitary ware, fittings, handles, and locks.

TiCN (Rose Gold): Warm and refined, combining modern aesthetics with premium texture, suitable for high-end jewelry, sanitary fittings, locks, and furniture accessories.

TiC (Black/Dark Gray): Sleek and stable, fitting modern minimalist styles.

TiAlN (Violet): A youthful and distinctive choice.

CrN (Silver White/Cold Silver): High reflectivity, closely resembling stainless steel.

Industrialization advantage: Equipment has been successfully deployed in sanitary ware, architectural hardware, and furniture accessories, achieving high-efficiency mass production with excellent consistency control.

Based on industry research data:

Rising penetration: The adoption rate of PVD in the decorative industry is expected to increase from less than 40% today to over 70% by 2030.

Driven by green manufacturing: With stricter environmental regulations and the accelerated phase-out of hexavalent chromium, PVD has become the inevitable choice.

Growing demand for personalization: The market is shifting from “classic metallic tones” to customized color systems, driving deeper collaboration between equipment manufacturers and brands.

Localization opportunities: Chinese equipment makers are breaking reliance on imports, becoming the technological backbone of high-end decorative brands.

Conclusion: “Chinese Intelligent Manufacturing” Empowering Decorative Aesthetics

Competition in the high-end decorative sector is moving beyond design into a deeper race of processes and materials.

With its unique blend of sustainability, functionality, and aesthetics, PVD is setting a new industry standard.

Leveraging four major platforms—Vacuum Evaporation, HiPIMS, Magnetron Sputtering, and Ion Plating—HCVAC has built a comprehensive coating ecosystem, enabling the decorative industry to achieve holistic upgrades in color innovation, protective performance, and eco-friendly manufacturing.

In the future, whether it is a luxury bathroom space or modern architectural hardware, the lasting brilliance and distinctive colors will increasingly be powered by the strength of Chinese Intelligent Manufacturing.