Customer base

Manufacturers of RFID related equipment and coating enterprises of related products

Solution

Manufacturers of RFID related equipment and coating enterprises of related products

Provide PVD coating equipment and technology for enterprises

Various types of RFID related products and growing customer demand, continuous development of a variety of equipment technology and coating process

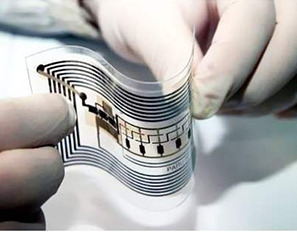

In terms of its external manifestations, the carrier of RFID technology is generally waterproof, antimagnetic and high temperature resistant, so as to ensure the stability of RFID technology in application. In terms of its use, RFID has advantages in real-time data updating, information storage, service life, work efficiency, security and so on. Radio frequency identification (RFID) can update the existing information more conveniently on the premise of reducing human, material and financial resources, so as to make the work more convenient; RFID technology stores information based on computers, up to several megabytes, which can store a large amount of information to ensure the smooth progress of work; the service life of RFID technology is long, as long as the staff pay attention to protection when using it It can be reused; RFID technology has changed the previous inconvenience of information processing, and realized multi-target identification at the same time, greatly improving the work efficiency; while RFID is also provided with password protection, which is not easy to be forged and has high security.

Huicheng vacuum coating equipment is a compact on-line equipment. The substrate carrier passes through the equipment in an upright manner. 12-16 substrates can be loaded into the same injection chamber each time. The injection chamber is a circular structure, equipped with a device to drive the carrier to rotate along the longitudinal axis to ensure that the substrate edge can also be coated. The process chamber consists of an etch unit for pre cleaning and substrate surface activation (to achieve better adhesion) and two planar DC sputtering sources for metal deposition processes. The chamber will be continuously pumped. According to the different reaction process formula, the tablet carrier will move in front of the process port according to the preset speed and frequency. During maintenance work, the process unit will be rotated to the large chamber door for easy operation. The terminal position of the process chamber is equipped with large blind flange to meet the needs of adding process chamber in the future.