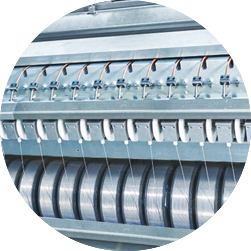

Capacitor roll to roll vacuum coating machine

HCCAP series machine can meet the requirements of capacitor metallized film in unlimited range. Aluminum or zinc aluminum can be evaporated to the surface of the film in vacuum. From standard to high-end applications, from thick film to thin film, from graphic design to sectional design, from thick layer to thin layer, from pure layer to laminated layer, all possible combinations can be realized in one system. The modular concept with multiple options and proprietary components makes the HCCAP series the standard product for mass production and the preferred system for highly complex applications such as ultrathin film and segmented patterns.

With more and more applications of electronic devices in daily products and industries, many new applications of thin film capacitors have been developed. They must reach the highest standards in terms of function, accuracy and service life, which is directly related to the requirements of miniaturization. Weight and space can be reduced by using the thinnest film. The processing of these high-tech materials, coupled with the precise deposition and segmentation of layer profiles, requires highly innovative, automated and reproducible production machine.

HCCAP series of devices are highly innovative, automatic and repeatable, and the film can meet the highest standards of application function, precision and service life. The flexibility of the system is key to success, with complex individual components integrated into the modular machine concept, enabling differentiation and allowing for optimized cost of ownership and high productivity.

Quality control technology, over bias technology for edges, special products, flexo based printing systems for high precision segmentation, flash based free edge oil evaporators for uniform edge generation, all combined with a powerful design for mass production of a wide range of products.

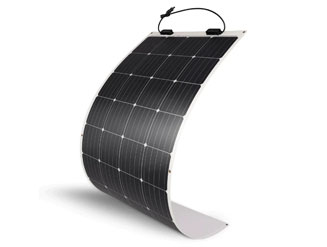

HCCAP series are widely used in electronic mobility, smart grid, renewable energy, construction and many other fields.