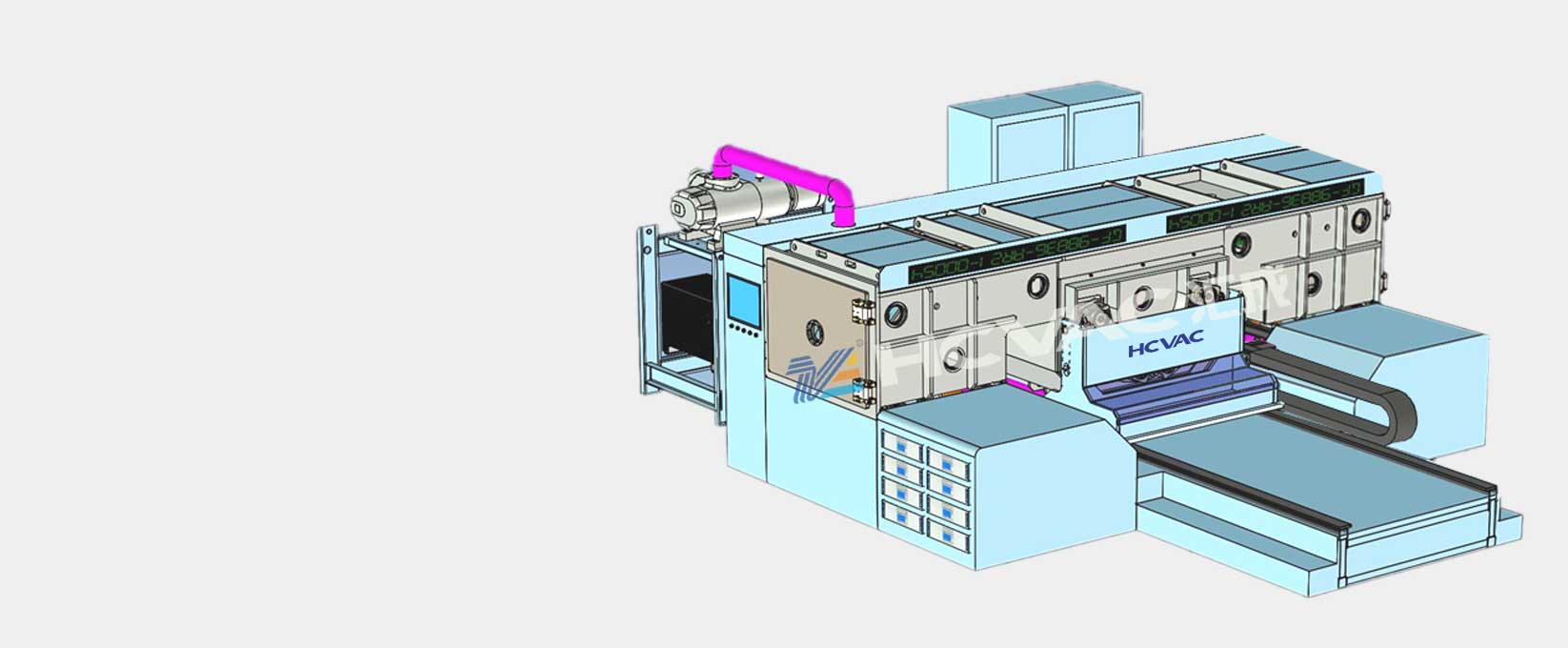

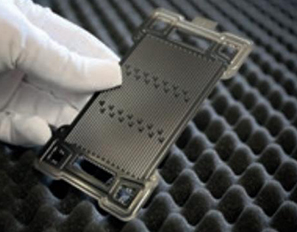

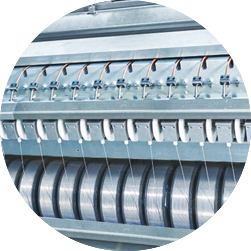

Experimental roll to roll vacuum coating machine

HCLAB series is a winding coating system based on modular, scalable and highly customizable platform, suitable for a variety of substrates and applications. It is designed for all processes and product qualification steps from laboratory to production. In addition, it is suitable for coating flexible glass.

HCLAB series uses the same key components as our wound coating systems for industrial production, but on a smaller scale, so our customers can test their applications in laboratory conditions and save time in upgrading their products to mass production.

HCLAB series concept offers a variety of winding system configurations. In addition, the roller section of the winding system can be reconfigured to meet new requirements and requirements.

HCLAB series machine is a small modular winding and coating system, which is specially designed for process and product certification from laboratory samples to mass production. In addition, it is also suitable for coating flexible glass. Although the machine is mainly suitable for small-scale production, it is also equipped with the same core components as the winding coating system for industrial production. As a result, our customers can test their applications in laboratory conditions and then scale up for mass production.